Download PDF

Download PDF

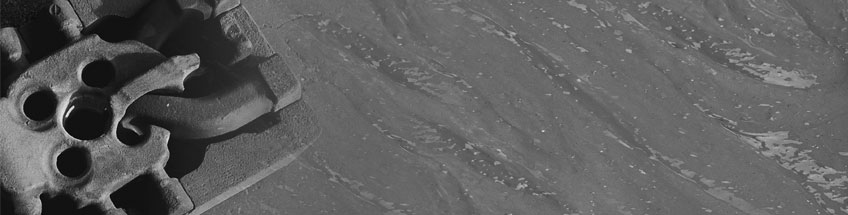

Alcohol Based Refractory Coating

Refex is a range of solvent based, ready to use coatings for application on resin bonded and silicate cores / molds.

Ignite the moulds or core immediately after coating application or dry by hot air or blower.

| Product | Color | Filler | Application |

|---|---|---|---|

| Refex–G | Black | Graphite | Gray with Iron, SG Iron, non ferrous casting |

| Refex–Z | Beige | Zircon Silicate | Thick castings of Iron & Steel |

| Refex–ZS | Beige | Zircon Silicate, Mixed Refractory | All Cast & Sg Iron Casting. Thin section Steel Casting |

| Refex–GZ | Red | Zircon Silicate, Graphite | All Cast & Sg Iron Casting |

| Refex–AG Refex–A |

Gray Rusty |

Aluminium silicates Graphite Aluminium silicates |

Thin walled Cast & SG Iron Medium sized cores of Cast & SG Iron |

| Refex–M | Creamy | Magnestie | Manganese Steel Castings |

NOTE: All information provided in this sheet is to the best of our present knowledge. No warranties or guarantee of any type or extent are intended or implied and the company accepts no liability for any loss or damage, consequential or otherwise. Any claim arising out of use of the product will be limited to replacement of material only.